Call Us: Mr. Amar Bahadur Singh +91 9839242388

Rug Process

RUGS MAKING PROCESS

Namrata Exports, is one of the most preferred handmade Indian carpet manufacturers. The company has made its presence as carpet manufacturers in Varanasi, India by providing the best quality carpets all over the world.Raw Material Selection

Raw Material Selection is one of the key part in the whole rug making process. The sheen and the feel of the finished rug highly depends on the way these raw materials are selected, spun, dyed and washed. Most commonly used materials in hand knotted rugs are wool and silk. Wool is mostly carded or spun by hand. Silk is mostly spun by hand. Namrata Exports uses best quality of raw materials.We provide best services during the whole rug making process or rug buying process. Our carpets are one of a kind and we are consistent in making same carpets in customized sizes.

Design Studio

Namrata Exports Design Studios explore the intersection of global, micro, and macro design trends and their applications in the built environment. Our designers share a belief in the creative process and a deeply-rooted passion to explore new design methods, delivering solutions to the market that have impacts on where we work, learn, heal, and live.Dyeing Process

Colouring yarn is a true art and there are many different ways of doing this. The initial way of doing it is however similar for all different methods, also the way that the yarns are prepared.When the yarn for a carpet is spun, the next phase is to colour it. This is a complicated process which demands knowledge and accuracy to achieve good results.D epending on the weather, the dyed yarn has to be dried in the sunlight for one to three days.

Latexing Process

Carpets are backcoated to make them more durable and readily handle. A good backcoating system serves to anchor the pile and prevent pull-out of the tufts, minimizes loosening of the pile, reduces shedding, provides dimensional stability and prevents fraying during cutting.Tufting Process

Weaving a rug using hand-tufted technique is a modern style.Hand-tufted rug is also known as a cut-pile rug.

Before starting the weaving process, a designer draws the design on a white paper and a graph is created. After that, weaver adjusts handloom according to the size of the carpet. Maximum three people work together in a single handloom. First, they stitch the cotton cloth as a frame on the loom which is called primary cloth and then draw a design on it. When CAD is ready then they start weaving using a gun machine. Gun machine is used for inserting wool material into the frame according to the design.

Finishing

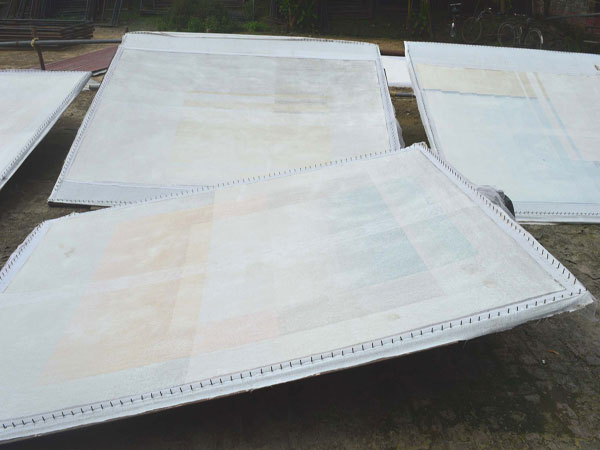

Once the yarn is woven into a rug, there are few steps in the final processing of the rugs.Trimming, washing, and drying of the rug – soon after the weaving, the rug is taken off from the loom for its trimming. The surface of the rug is smoothening out by removing extra hanging fibers. Pointed sharp scissors are used for this leveling. This trimming brings out the clarity in the design of the rug. After trimming, the rug is washed with detergent and later with only with clean water to get rid of all the dirt and leftover detergent. Later the rug is left under sunlight for drying for about four-five days.

Packing Process

After the carpet is finished, it is packed and bailed for exports.The process of Rug Packing at Namrata Exports is conducted in the following process:

1. The manufactured carpet is rolled around the card board pipe.

2. A white transparent plastic sheet is wrapped around the carpet.

3. An adhesive tape is tied around to secure the plastic over the carpet.

4. The brand identification mark on a silken tag, is sewn below the pile. The tag carries the logo and name of the company along with the care instructions.